A Range Of Fabric Expansion Joints For Critical Applications From the leading manufacturer of Fabric Expansion Joints in India.

INSAPLEX is a member of the diversified industrial group - IGP. The IGP group has been serving the Core Industry for over six decades, with a revenue in excess of INR 6000 million.

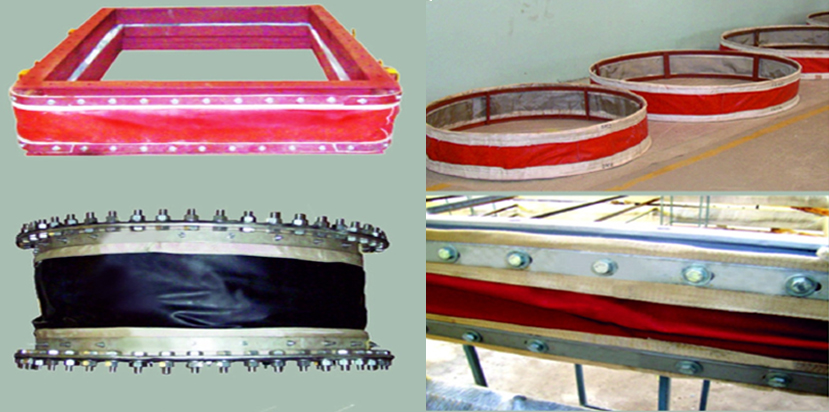

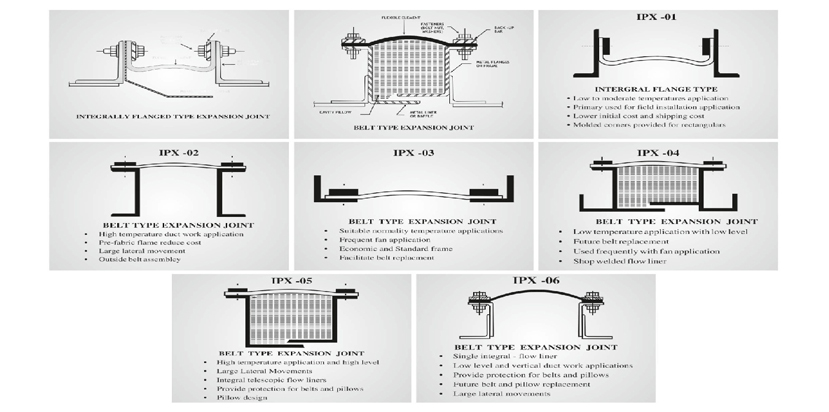

INSAPLEX manufactures FABRIC EXPANSION JOINTS for use in Flue Gas Ducts, Process Gas etc, for accommodating movements at medium to high temperature conditions. These bellows are manufactured using different types of raw materials to suit customer requirements.

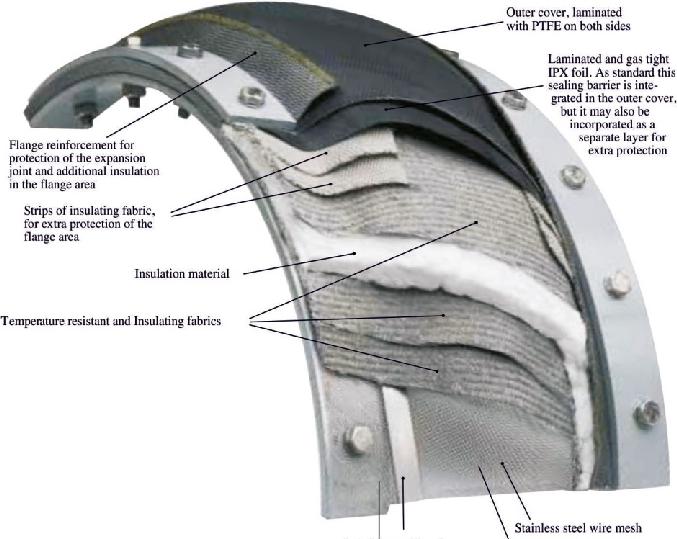

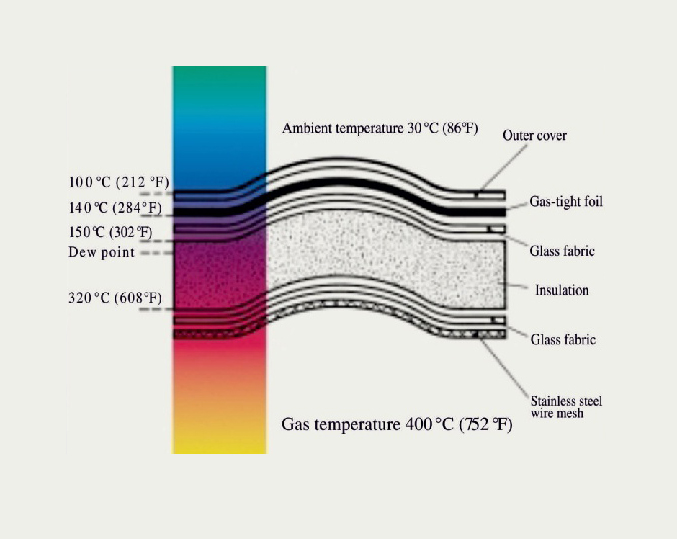

INSAPLEX FABRIC EXPANSION JOINTS (FE joints) are robust, highly flexible expansion joints constructed from layers of synthetic cloth embodying a pressure membrane of reinforced PTFE. They are cost-effective, particularly in low pressure applications up to 14.7 P.S.I.G.

Materials used in these bellows range from Glass fabric (Neoprene Coated, EPDM Coated, Silicon Coated), PTFE , Mineral wool, Ceramic fabric and SS Wire cloth.

Proven design & construction for continuous high temperature environment, even up to 1000°C.

Size as large as 6000mm dia in circular and any transportable size in Rectangular as total assembly.

Expertise to develop and supply for every end use in Power, Metallurgical and Process Plants.Accredited with ISO 9001 :2008. Huge resources for emergency supply.

All fabric expansion joints are fully customized according to client's request and requirement.

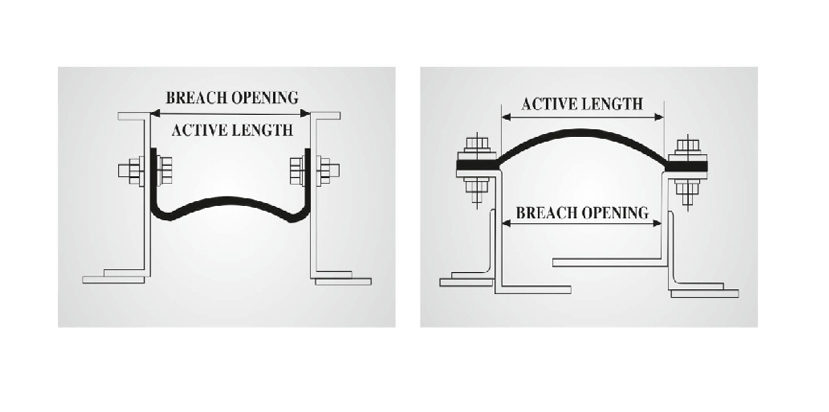

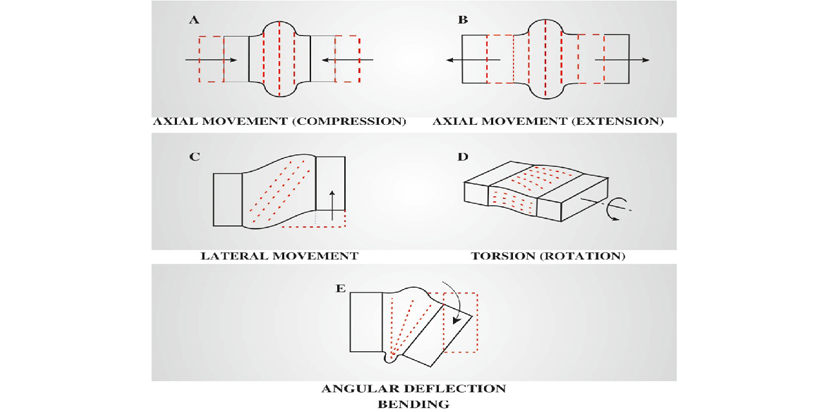

Non-metalic ducting movements can be calculated on the design and maximum excursion temperatures. One unit of fabric expansion joint is able to handle combined axial. lateral, angular and torsional movements. The expansion joint are carefully placed to minimize the number of expansion joints required while absorbing all of the duct movements