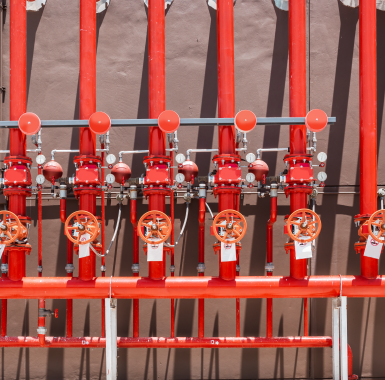

WHERE IS IT USED?

PTFE-lined Hoses are utilized as balancing elements between engineering parts. Due to the different geometry of the folds, highly flexible or pressure-resistant versions can be designed and manufactured. PTFE’s outstanding material properties allow Hoses to be used progressively in medical, food, and general industrial applications.

INDUSTRIES

Industries where highly corrosive materials are used in any area of the chemical process, make use of PTFE-lined Hoses.

Enhances operational safety for personnel, processes, and plants when handling highly hazardous materials.

Where pipe replacement is frequently difficult or impossible.

Foods, pharmaceuticals, and fine chemicals.

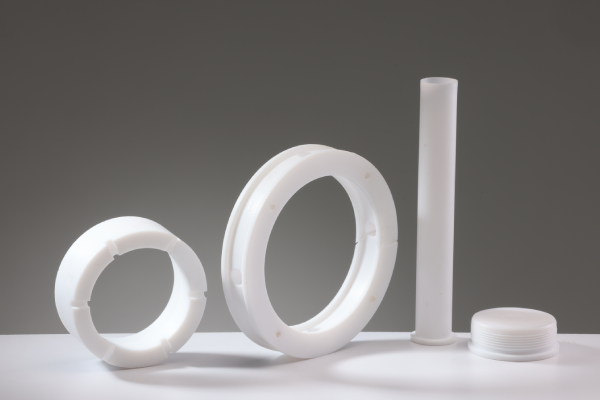

LINED BELLOW RANGE

INSAPLEX Hoses for most sizes as standard and manufactured from virgin PTFE combined with a multi-layered austenitic stainless steel shell to provide high pressure performance. This range is designed to the EJMA international standard.

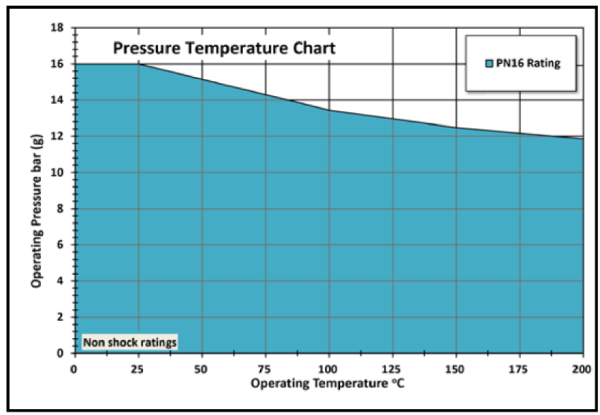

PTFE HOSES Range – DN40 to DN500

| Temperature/Vacuum | 1.1/2" - 4"NB | 5"NB | 6"NB | 8"NB | 10"NB | 12"NB | 14"NB | 16"NB | 20"NB |

| DN40 - DN100 | DN125 | DN150 | DN200 | DN250 | DN300 | DN350 | DN400 | DN500 | |

| 20°C / Bar(g) | -1.0 | -1.0 | -1.0 | -0.98 | -0.95 | -0.89 | -0.82 | 0.0 | 0.0 |

| 100°C/Bar(g) | -1.0 | -1.0 | -1.0 | -0.95 | -0.87 | -0.77 | -0.64 | 0.0 | 0.0 |

| 180°C / Bar(g) | -1.0 | -0.97 | -0.95 | -0.88 | -0.77 | -0.64 | -0.47 | 0.0 | 0.0 |

MATERIAL SPEC & STANDARD

| Materials | |

| Component | Materials |

| Bellows Liner | Paste Extruded Virgin PTFE to ASTM D4895 |

| Bellows Shell | Stainless Steel to 321S31/321/1.4541 |

| Flanges | Carbon Steel to S235JRG2 / RSt 37.2 |

| Paint on CS flanges | Zinc Epoxy Primer, Colour Grey |

| Options | |

| Bellows Liner | Paste Extruded Static-DissipatingPTFE to ASTM D4895 |

| Bellows Shell | Hastelloy & other Exotic Materials |

| Flanges | Stainless Steel, Exotics etc. |

| Bolt Holes | Threaded Holes UNC or Metric |

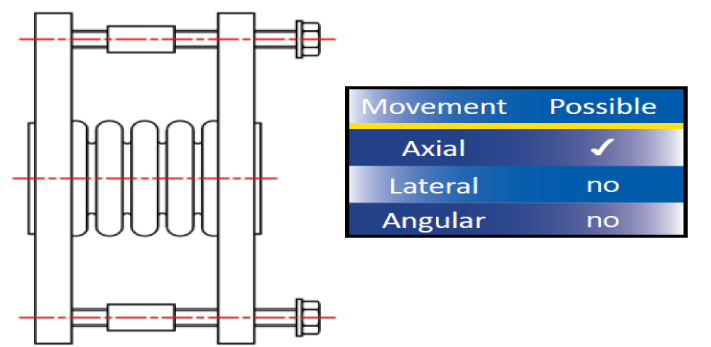

| Tie Rods | Available as an option |

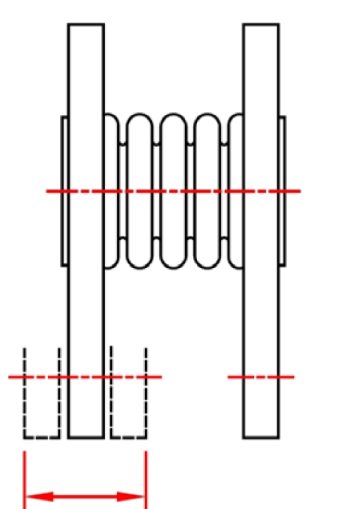

EXPLANATION OF MOVEMENTS

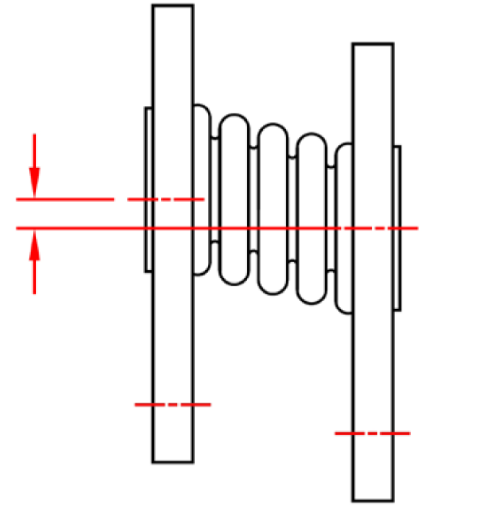

Axial

Lateral

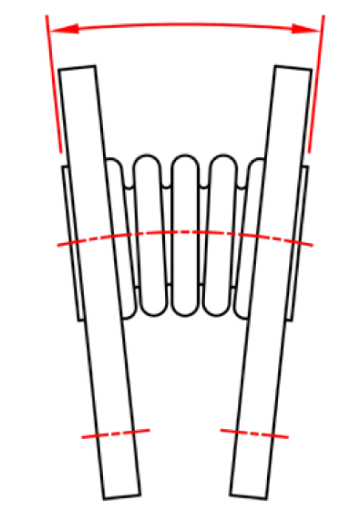

Angular

Large Movement

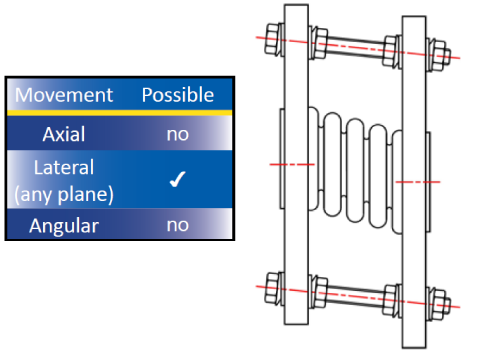

Lateral Hoses

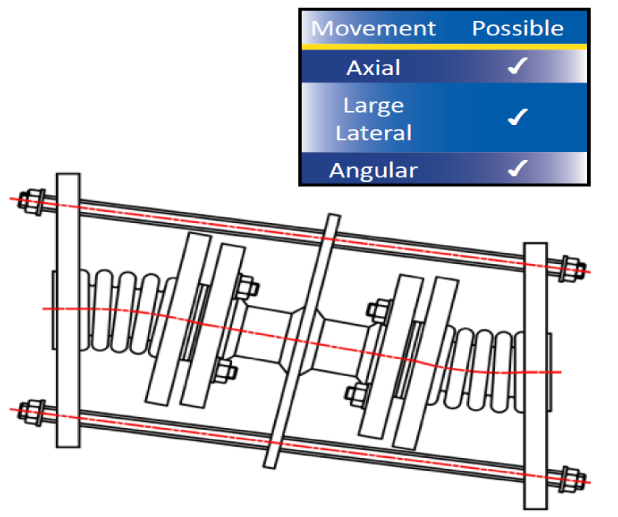

[Universal Hoses]

Axial Only Hoses

[Axial Hoses]

Lateral Only Hoses

[Lateral Hoses]

All Planes

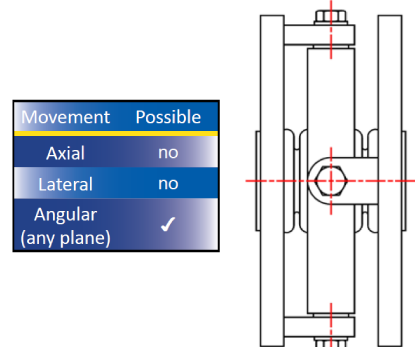

Angular Hoses

WHAT IT DOES?

PTFE is a highly effective polymer that is recognized for its superior chemical resistance, low friction, and high-temperature resistance. Its unique properties make it a suitable choice for a wide range of applications, making it a versatile material. PTFE has a low co-efficient of friction, which is a unique characteristic. It’s an excellent choice for use in applications where low friction is necessary due to its lower co-efficient of friction than any other solid material.

WHAT SOLUTION DOES IT OFFER?

PTFE is commonly used as a coating to decrease the co-efficient of friction of other materials. PTFE is a highly effective electrical insulator with a high dielectric strength, allowing it to be used in electrical and electronic applications where high-temperature resistance and good electrical insulation are necessary.

FEATURES

PTFE is a fluoropolymer that is not only affordable but also has the best performance-to-price ratio on the market. Filled PTFE retains its chemical and high-temperature properties, but the addition of fillers enhances its mechanical strength, stability, and wear resistance.

We have the ability to produce components using more than 500 grades of PTFE, and help you make the perfect choice for your project.

It is capable of operating at temperatures from 200°C to +/- 260°C with high-temperature resistance.

The mechanical toughness is exceptional at -180°C with low temperature resistance.

It has a high lubricating property.

Excellent insulation properties.

Non-sticky quality & Non-hazardous

Anti-corrosion & long durability

MANUFACTURING PROCESS

PTFE products are manufactured using cold compression molding and sintering processes, as well as isostatic molding and sintering processes. RAM extrusion, paste extrusion, hot coining process, skiving process, calendaring process, coating process, and machining are all involved in the production of a final component.