WHERE IS IT USED?

polyetherketone has acquired prominence in a variety of industries, including aerospace, automotive, electrical and electronics, and medicine. PEEK can be used to replace aluminium and other metals in aircraft components in the aerospace industry. It is employed in crucial engines, aircraft exterior and interior elements, and provides exceptional resistance to high temperatures. PEEK offers weight reduction and noise reduction in the automotive business, resulting in metal substitution. The structure of PEEK the reaction mechanism behind it and the comparison of various PEEK versions with other high-heat plastics the suitable processing conditions and final products are available for use.

INDUSTRIES

WHAT SOLUTION DOES IT OFFER

High-performance bearings and gears

Is capable of handling demanding conditions due to its strength, wear resistance, and high-temperature capabilities.

Aerospace and automotive components

A material that is light and robust can be used for parts that are exposed to high temperatures and stresses.

Medical implants

Artificial joints and other medical devices are made of biocompatible grades.

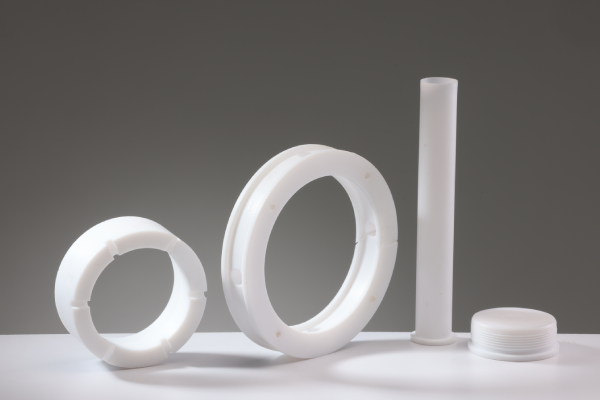

Pump and compressor parts

Ideal for components that handle corrosive fluids and operate at high temperatures.

Electrical and electronic components

High-temperature insulation and structural solutions for demanding environments.