WHERE IS IT USED?

Fluoropolymers are widely used in industries and applications due to their high-performing properties. Our production capabilities range from fluoropolymer-insulated components found in everyday electrical devices to high-performance seals used in the energy industry, all designed specifically to meet your requirements.

INDUSTRIES

This serves as a moisture barrier for both food and pharmaceutical blister packing.

In electroluminescent lamps, a water-vapor barrier is used to protect the phosphor coatings, which are sensitive to moisture.

PCTFE is helpful in the production of semiconductor components such as water boats due to its strong strength and electrical qualities.

PCTFE is helpful in the production of semiconductor components such as water boats due to its strong strength and electrical qualities.

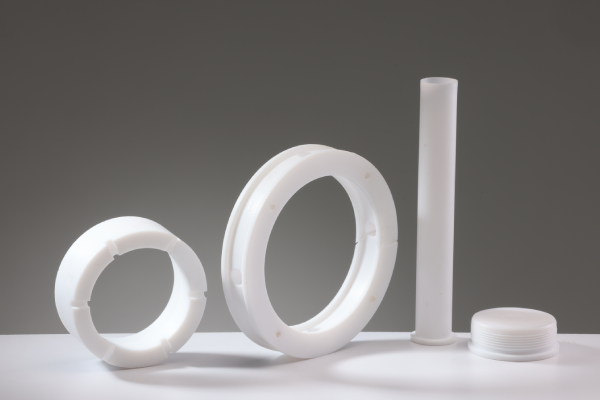

The use of this material is applicable to seals, O-rings, gaskets, valves, and tubes.

It is used to safeguard sensitive electronic components because of its electrical and water resistance.

PCTFE, or Poly Chlorotrifluoroethylene, is a high-performance polymer that has numerous applications in a variety of sectors. Its extraordinary features, including remarkable strength, resistance to a wide range of chemicals, and water repellence, make it an excellent choice. In situations where other plastics may fall short, PCTFE shines, offering a one-of-a-kind and highly effective solution. PCTFE’s exceptional properties make it a dependable and effective material for a wide range of applications, whether in engineering, aerospace, defences, pharmaceuticals, valves or other industries.

WHAT SOLUTION DOES IT OFFER?

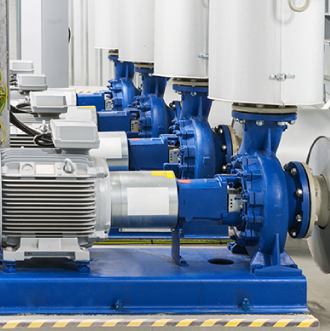

Polychlorotrifluoroethylene (PCTFE) is a versatile fluoropolymer that is widely used in a variety of industries. PCTFE is highly desired in severe industrial conditions due to its superior chemical resistance, thermal stability, and low gas permeability. It is widely used in sealing and gasket materials for industries such as chemical processing, oil and gas, pharmaceuticals, and semiconductor production, where its chemical inertness assures reliability in the presence of corrosive substances. PCTFE’s versatility extends to specialized components such as valves and pumps, which provide consistent performance in a wide range of temperature ranges, while its low gas permeability is critical in aeronautical and cryogenic systems.

FEATURES AND BENEFITS

PCTFE is particularly useful in tough industrial situations. A primary application is in sealing and gasket materials for industries such as chemical processing, oil and gas, pharmaceuticals, and semiconductor production, where its chemical inertness assures dependability in the presence of corrosive substances. PCTFE’s versatility extends to specialised components like valves and pumps, which provide constant performance in a variety of temperature situations, while its low gas permeability makes it essential in aeronautical and cryogenic systems. Furthermore, PCTFE’s transparency to a wide range of electromagnetic radiation makes it a popular material in the optical industry, where it is used to manufacture optical windows, lenses, and components that require clarity and resilience to environmental influences.