WHERE IS IT USED?

In Aerospace

Rubber gaskets play a crucial role by sealing flanges and

joints, preventing the leakage of fluids and gases. Their

ability to withstand a wide range of temperatures and resist

aviation fuels makes them well-suited for the demanding

aerospace environment.

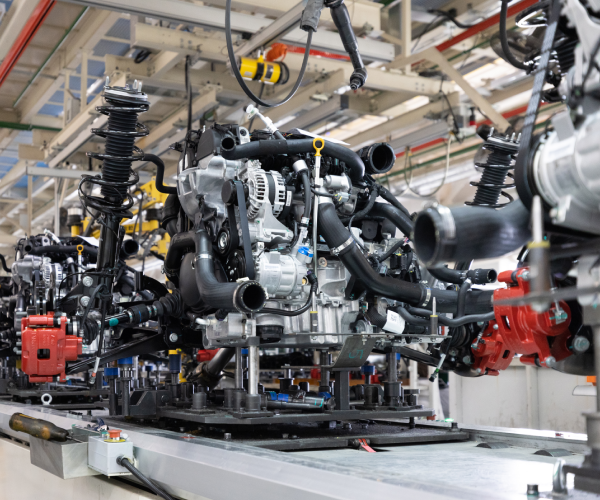

In Oil and Gas

In the oil and gas industry, rubber gaskets use to Prevent the leaks and available in various size, shape, suitability to ensure the piping system as per industrial standards.

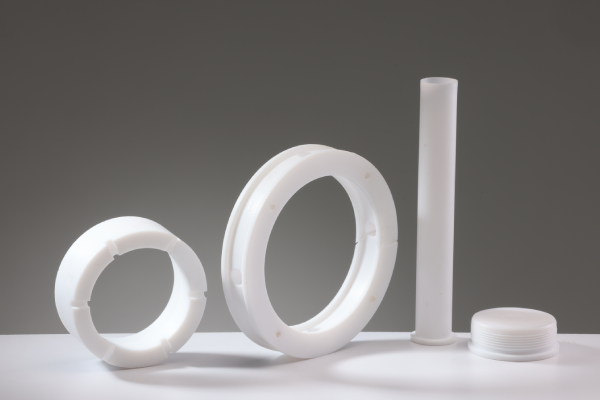

What It Does

Rubber gaskets serve as sealing components, preventing fluid or gas leakage between joined surfaces, and find various industries like power plants, petro chemical industry & industrial equipment, machineries.

FEATURES AND BENEFITS

Exceptional Elasticity

Conforms to irregular surfaces for a secure, airtight seal.

Insulation Properties

Effective sealing against leaks.

Cost-effective

Economical and customizable, a preferred choice for manufacturers.

Elasticity, Durability, Chemical Resistance

Key features ensuring effective and lasting seals in diverse industrial applications.

MANUFACTURING PROCESS

Gasket Template and Design

Our Rubber Gasket manufacturing starts

with our own rubber compounding design,

based on customer requirements.

Manufacturing

Precision and quality are a given in every gasket manufactured at Insaplex. Through strenuous quality control procedures which include conducting material integrity inspections and maintaining dimensional accuracy, we ensure that each gasket meets required specifications and standards.