WHAT IT DOES

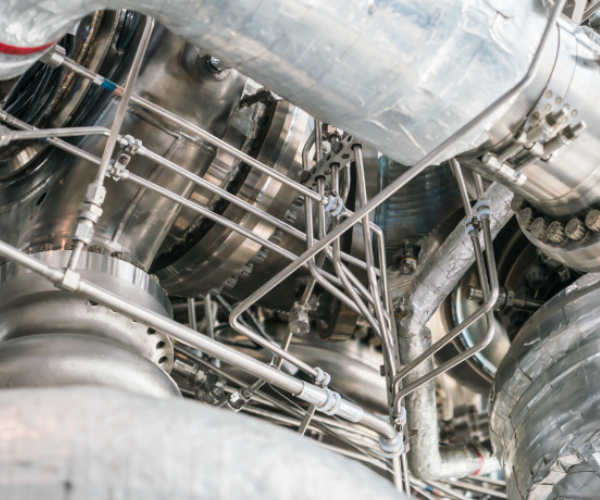

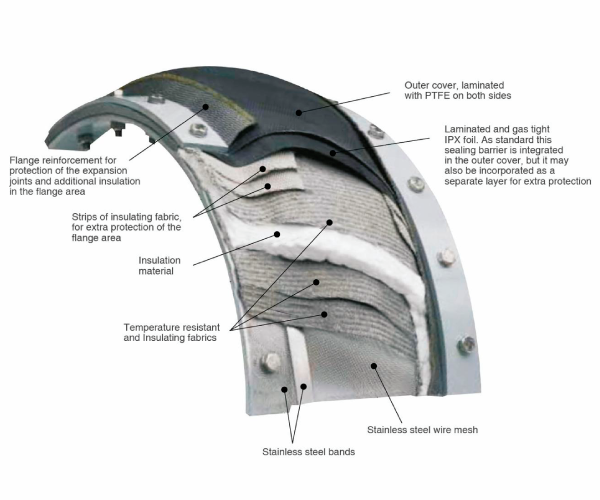

Composite expansion joints in industrial settings effectively manage thermal expansion, misalignment, and vibration in ducting systems. Comprising a flexible element with multi-layered composite fabric between two metal frames, these joints accommodate movement while maintaining a secure seal.

WHAT SOLUTION DOES IT OFFER?

Composite fabric expansion joints address various challenges in industrial ducting systems

Thermal Expansion

Accommodates thermal expansion by extending and contracting along with ducts, preventing stress build-up and potential leaks.

Misalignment

Acts as flexible connectors, bridging gaps caused by imperfect connections or movements during operation. Allows for small misalignments without compromising the seal or flow, reducing wear and tear on equipment.

Vibration Isolation

Serves as vibration dampers, absorbing and isolating vibrations caused by the movement of sources through ductwork. Promotes quieter operation and protects sensitive equipment.

FEATURES AND BENEFITS

Application

Commonly used in low-pressure ducting applications.

Functions

Effectively balances misalignment, vibration, and thermal growth.

Versatility

Valuable solution for various industrial ducting applications

Characteristics

High flexibility, lightweight design, temperature and chemical resistance. Low maintenance requirements, reduced spring rates and loads vibration dampening, sound attenuation.

MANUFACTURING PROCESS

Bonding and Joining

The layers of the composite material are joined using bonding techniques, employing methods such as sealing, heat, or other suitable approaches for the chosen materials.

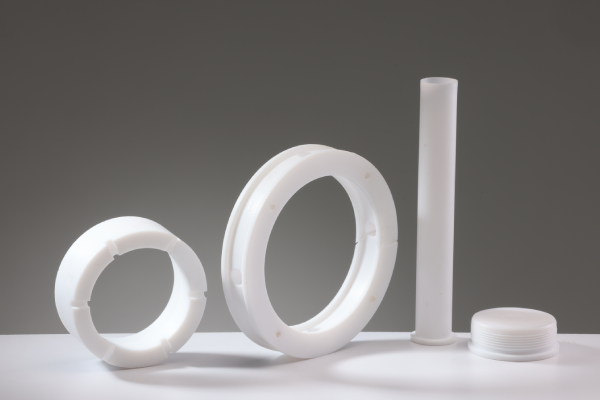

Fabrication of Composite Sheets

Sheets are composed by layering and combining different materials through techniques like weaving, knitting, or laminating.